Cardboard is a widely used material that plays a crucial role in packaging and construction. While standard printer paper ranges between 70 and 90 gsm, cardboard boasts a heavier paper weight, which adds to its sturdiness. In this article, we’ll thoroughly delve into the unique layers and structure of this heavyweight paper that make it a go-to choice for applications requiring both durability and flexibility.

Cardboard explained briefly

Cardboard is an umbrella term for heavy-duty paper that is made of multiple layers of paper pulp and typically used for cards, puzzles, book covers, and boxes.

Inhaltsverzeichnis

Definition: Cardboard

Cardboard refers to a thick, sturdy paper-based material that is commonly used for packaging and bookbinding purposes. It’s typically made from softwood trees and can vary in paper thickness, strength, and texture. Unlike regular printer paper types, cardboard is typically made by pressing several layers of paper together to create a multi-layered structure. This structure makes it quite sturdy, and if uncoated, it’s also biodegradable and can decompose within five months under ideal circumstances.

Hardcover with individual embossing

- Price calculator & 3D live preview

- Professional binding for thesis, dissertation, or books

- Print on demand with fast delivery right to your doorstep

Learn more!

How to make a cardboard box

Cardboard is made from softwood trees, such as pine or fir trees. This is because they have long fibers, which can hold a lot of tension, making them perfect for producing rigid cardboard boxes.

- The trees are first chopped, debarked, and chipped into large amounts of smaller pieces with a so-called chipper machine.

- They are then formed into a brown wood pulp through the mechanical or chemical pulping process, similar to ordinary paper.

- The raw material is put into a corrugator to create wavy flutes in the middle layer for high stability and flexibility. Different corrugator machines create different flute sizes.

- The wavy material is then sprayed with an adhesive so it sticks to the flat linerboards and later folded into its final box form.

Uses

As cardboard is a very versatile material, it has many uses that even go outside the usual packaging purposes.

- Aperture cards

- Business cards

- Paper rolls

- Jigsaw puzzles

- Hardcover bookbinding

- Display boards

- Pizza boxes

- Scrapbooking

- Playing cards

- Postcards

- Catalog covers

- Storage boxes

- Packaging

- Drink carriers

Types

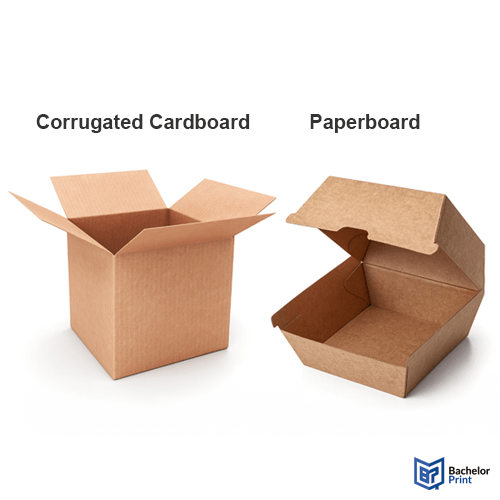

Cardboard comes in numerous types: corrugated cardboard, paperboard, honeycomb, and mat board. Each one will be explained below.

Corrugated cardboard — or corrugated fiberboard — is a three-ply paper construction that has two flat outer layers (liners) and a wavy layer (flute) between the outer layers.

It’s easy to bend, cut, drill, and fold, yet still durable. Corrugated fiberboard comes in different thicknesses that are typically labeled from A to F, with A being the thickest and widest flute.

It’s used for:

- Packaging

- Moving boxes

- Shipping boxes

Paperboard — also referred to as chipboard or carton — is a single-ply, thick paper construction. It’s usually thinner and lighter than corrugated cardboard and has a smooth surface.

It’s not unusual for this type of cardboard to have a paper coating.

It’s used for:

- Food boxes

- Cereal boxes

- Playing cards

Honeycomb cardboard is not a common type when it comes to packaging, as it’s used for heavy-duty packaging and construction.

It consists of a core of hexagonal cells made from paper that is sandwiched between two thin layers of linerboard. This design mimics the structure of a honeycomb.

It’s used for:

- Electronics

- Fragile items

- Furniture packaging

Mat board is a type of cardboard with a smooth, textured finish. This type of cardboard is primarily designed for aesthetic purposes rather than structural ones.

It’s used for:

- Picture framing

- Artwork framing

Structures

Corrugated cardboard is constructed with multiple layers, including the flat (inner or outer) liners and the wavy flute in the middle.

The term “liner” (or linerboard) refers to the flat outer layers that provide cardboard with its strength and protection.

The flute (or medium) is the wavy inner layer that acts as a cushion, offering additional resilience and insulating properties.

Board styles

For added protection, corrugated cardboards can have multiple layers. The board styles below show how these layers are combined.

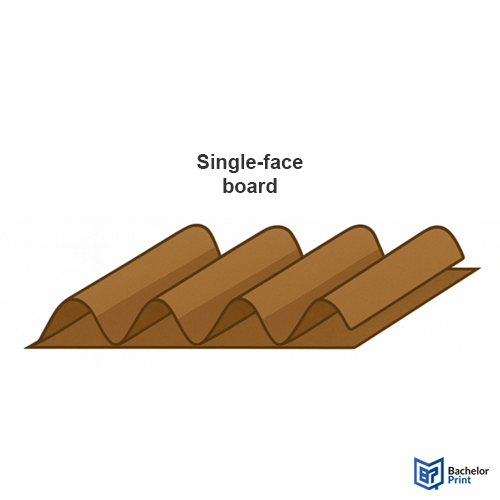

Single-face board

Single-face cardboard is sold in rolls and made of two layers: one singular liner glued to one corrugated layer. Due to it only having a singular liner, it’s not as durable as the other board styles, yet still ideal for extra cushioning inside boxes or for wrapping fragile products in.

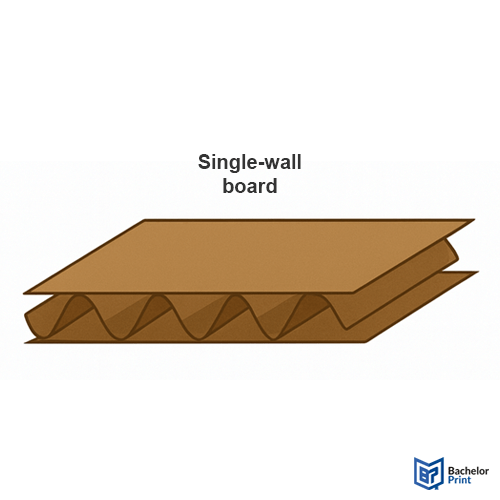

Single-wall board

Single-wall cardboard is the most common type used for shipping and packaging and consists of three layers: one flute glued between two outer layers. It’s also known as 3-ply cardboard and can — depending on the type — carry around 15 kg (35 lb) on average.

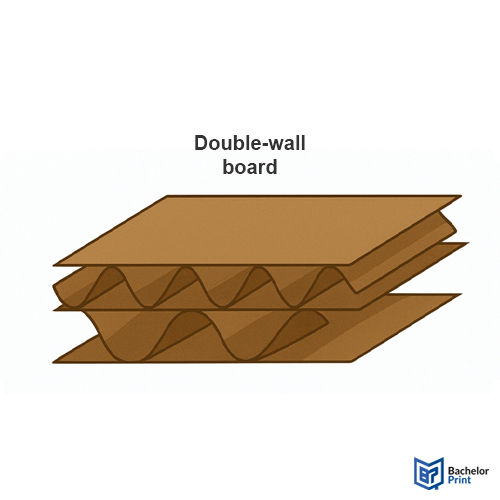

Double-wall board

Double-wall cardboard is used for heavier shipping boxes and is made of five layers: between the two outer layers are two corrugated layers that are separated with a single liner. It’s also known as 5-ply cardboard and can carry an average of 54 kg (120 lb).

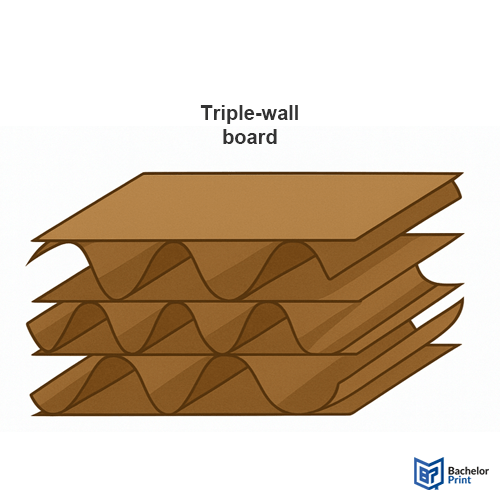

Triple-wall board

Triple-wall cardboard can be used for delicate shipping crates like chemical containers, as they’re as sturdy as wooden crates. This type is made of a total of seven layers: two outer liners, two flutes, two liners, and one flute. It’s also known as 7-ply cardboard and supports an average of 90 kg (200 lb).

Flute styles

The flute’s design is critical to the cardboard’s overall structural integrity, as its air pockets not only provide strength but also flexibility to the material. Larger flutes like A or B flutes are ideal for heavier items, while smaller flutes like E or F flutes are better for lightweight items. It’s also possible to combine one or more flutes to create grades like the “BC” flute. The most common ones are listed in the table below.

| Flute | Profile | Flutes per foot | Thickness | Benefits |

|---|---|---|---|---|

| A |  |

36 | 1/4” |

|

| B |  |

49 | 1/8” |

|

| C |  |

41 | 11/64” |

|

| E |  |

90 | 1/16” |

|

| F |  |

128 | 1/32” |

|

In the table, “flutes per linear foot” refers to the number of flutes in a given length of cardboard, which is typically measured in feet.

Printing services at BachelorPrint

- Individual solutions & personal support

- High print quality & fast production times

- Wide range of print products for every need

Learn more!

Printing

Cardboard can be printed on using numerous methods, which is why we have listed the most common printing techniques for it below.

- Offset printing

- Screen printing

- Digital printing

- Flexography printing

You can find out more about these printmaking methods by clicking on the button below.

FAQs

Triple-wall cardboard is a type of corrugated cardboard that has seven layers: two outer liners, two wavy flutes, another two liners, and another wavy flute in the middle. This makes it extremely strong for heavy-duty packaging.

Cardboard is made of softwood trees, e.g., pine trees, since they have long and strong fibers.

The softwood trees are cut down, debarked, and chipped before they undergo the pulping process, similarly to printer paper. After this, the wood pulp is put into the corrugator machinery that crimps the middle layer of the cardboard. Then adhesive is added to glue each layer together and later folded into a box.

It takes cardboard around two to five months to decompose, especially when exposed to the elements.