The best advantage of solid inks is that they can be stored for a long time without the risk of drying because they are already solid. So, naturally, many printing companies are impressed by these printing inks. One type of them is the sublimation ink, which is highly special, as the printer turns it from a solid state immediately to gas without first liquefying it. This article will tell you all about the topic and provide arguments for and against sublimation ink.

Definition: Sublimation ink

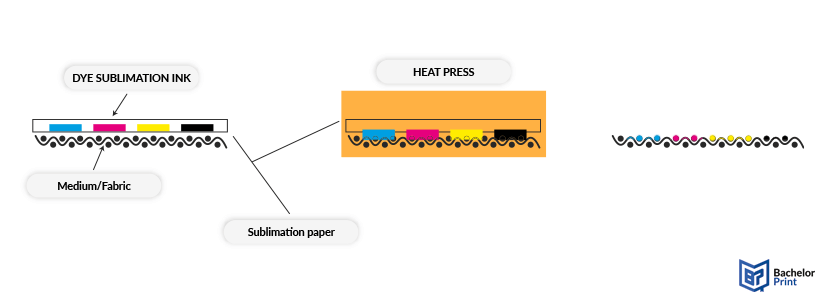

Sublimation ink is a type of dye-based solid ink that is used in sublimation printers. It is heated to the point where it turns to gas without first liquefying. This allows the ink to penetrate the medium and leave a durable and long-lasting image. The ink is therefore first printed onto a transfer paper, before the heat press forces it into the medium.

Applications and limitations

The process of sublimation ink printing is quite intricate. First, the image is printed on heat transfer paper using a sublimation printer or an upgraded inkjet printer. Thereafter, the paper is pressed onto the medium, mostly polyester fabrics, and heated. The heat and pressure allow the ink particles to turn into gas, permeating the fabric. Cotton or other heat-sensitive fabrics are not advised for use. Other possible applications include ceramics, wood, metal, glass, cardboard, and other materials. The most widely known is printing on clothes and personalized cups.

However, every surface printed on must be either made from polymer/polyester or coated with polymers. This poses a risk to the environment and has sustainability issues. Furthermore, sublimation ink is also meant to be used on white or lighter surfaces, as the dye is often translucent.

Printing services at BachelorPrint

- Individual solutions & personal support

- High print quality & fast production times

- Wide range of print products for every need

Learn more!

Advantages and disadvantages

Sublimation inks have many advantages and disadvantages to consider before deciding on using them.

Advantages

- No smudging because it is turned into gas without first liquefying

- Durable due to the penetration of specific types of medium

- Quick and easy customization due to using offset printing

- Versatile in material application

Disadvantages

- Not all types of medium are possible due to the heat and base color

- High initial costs and pricey for middle volume quantities

- Not environmentally friendly because the printing surface must be polymer-coated

- Slow and elaborate printing process

FAQs

Sublimation ink is a type of solid ink that is heated under pressure until it turns to gas as part of the printing process, creating a vibrant and durable image.

Sublimation ink is used for vibrant, durable, and quickly customizable prints on various surfaces such as polyester fabric for clothes, ceramics for mugs, or wood for designs and art prints.

While sublimation ink has a wide variety of applications, there are also some limitations. For example, the surface needs to be covered in polymer if the material is not made from plastic itself. Furthermore, sublimation inks work best on white or at least lightly colored surfaces. Lastly, the medium needs to be heat-resistant, which excludes many natural materials.

No. The best option is a special sublimation printer, which is manufactured for sublimation printing. Other than that, some inkjet printers can be alternated with a specific printing head to be able to print with sublimation ink.