Print finishing is, in most cases, associated with enhancing the visual of a print to make it more appealing to customers, such as product packaging, certificates, or invitations. However, print finishing can also elevate the durability and resistance of a print. One way to achieve this is lamination, a method where the paper sheet is enclosed in plastic foil. The process and details of this procedure shall be explained thoroughly in the following article.

Inhaltsverzeichnis

Definition: Lamination

Laminating is the process of enclosing a sheet of paper between foil or plastic to make it waterproof, scratch-resistant, and overall, more durable. There are different types of lamination films, such as matte or glossy, which are measured in mil. One mil is 1/1000th of an inch, or 0.001 in, and must not be confused with a millimeter. The lamination often reaches over the edges of the paper to make sure the sheet stays untouched by any outer influence. This should be considered especially when the print is supposed to fit into a folder.

Printing and laminating at BachelorPrint

- Vivid colors & sharp details on premium materials

- Print & laminate menus, posters, certificates & more

- Durable lamination to protect your documents of any size

Learn more!

Types

In total, there are four types of paper laminations: gloss, matte, soft-touch, and dry-wipe lamination.

Gloss lamination provides a shiny finish to the documents. It is the most common and thus cheapest option to get. It is durable, easy to clean, and makes colors pop out due to contrasts. On the other hand, the reflections of the gloss might make the print unreadable from certain angles, and scratches or fingerprints show up more prominently.

Matte lamination is the non-reflective counterpart to the glossy one, offering an equally affordable price due to the similarity. The softer surface creates a pleasing feeling while still maintaining durability and resistance. However, the contrast between the colors is not enhanced, meaning images will not show up as vibrant as with a glossy lamination.

Soft-touch lamination is similar to the matte one but provides an intensified touch experience. The luxurious finish appears exclusive and professional without losing durability. This also comes with a higher pricing of the materials, as well as less color vibrance, just like with matte lamination.

Dry-wipe lamination is made for writing and erasing on the laminated sheet of paper, such as empty grocery lists to fill in or checklists. Thus, it is also the most durable lamination of them all. However, it is also expensive and offers no visual benefits to the print.

Advantages

Laminating holds many advantages for your print, not only in durability, as the following list shows:

Pros

- Protection against forgery

- Durability of the documents

- Makes colors appear more vibrant

- Professional, high-quality appearance

- Perfect finish without creases or wrinkles

Hot vs. cold laminators

There are two main types of lamination processes: hot and cold. Generally, hot lamination is preferably used for smaller prints, while cold lamination finds application in large prints like signs.

Hot laminator

Hot laminators enclose the sheet of paper between two sheets of plastic, which are heated up inside the device to slightly melt around the piece of paper. This ensures a waterproof and highly resistant product made for longevity.

The device used is often a pouch laminator with 2-6 rolls pressing the sheets together. It is rather small and can easily be moved from one table to the next in an office.

Cold laminator

Cold laminators, on the other hand, trap the sheet between plastic films that adhere to it by using glue. This technique is mostly used for temperature-sensitive prints.

For this process, usually film roll laminators are used. They are bigger machines, often found in print centers, which specialize in high-volume lamination. However, these machines are expensive and impractical for small offices.

Affordable document printing from $0.10

- Crisp text, vibrant colors & multiple paper choices

- No need to visit a shop; simply order online anytime

- Print documents, copies & reports with professional quality

Learn more!

Different materials

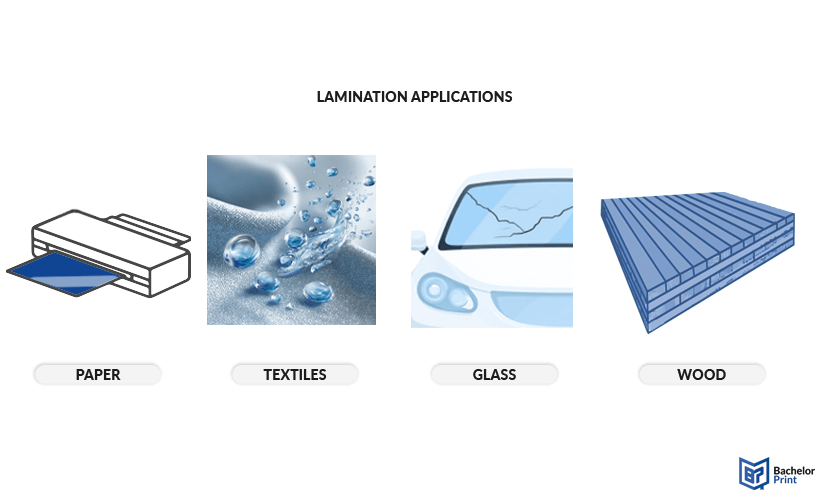

Lamination is not only restricted to print finishing. There are many other categories where similar processes are used to enhance the durability of various surfaces.

Paper

The most common laminating practice is enveloping a sheet of paper in plastic films to make it more durable and water-proof.

Textiles

Textiles can be soaked in lamination liquids to make them waterproof, durable, or more resistant against fire, chemicals, and other dangers and suitable for using with a sublimation printer.

Glass

Glass, for example in windshields, mirrors, or windows, is often laminated to prevent glass shards from spreading if it shatters.

Wood

Wood can be laminated either for protection, as in laminated flooring, or it is used to assemble multiple planks into a piece bigger than normal trees can provide.

FAQs

Laminating a piece of paper is rather simple. The sheet is inserted in a laminator, which either encloses it in plastic by melting it around the paper as a hot lamination or the plastic adheres to the paper with glue.

Depending on your country’s rules, it might not be illegal. However, it is not advised to laminate official documents such as birth certificates or Medicare cards, especially when the paper has some anti-forgery characteristics that might get lost in the lamination process.

Thermal paper cannot be laminated in hot lamination, as it reacts to the heat. However, using cold lamination, where the sheets are connected with glue, is possible. Apart from the printer paper types, specific inks such as fluorescent ink are also not recommended for lamination due to adhesion difficulties.