Gauze is a light, open-weave fabric that plays a crucial role in modern bookbinding and professional bookbinding materials. Used primarily to reinforce the spine, it adds flexibility without sacrificing strength. Whether you’re crafting journals at home or producing library‑grade hardcovers, gauze ensures pages open smoothly and resist wear. Discover how this binding material can enhance your next project.

Gauze explained briefly

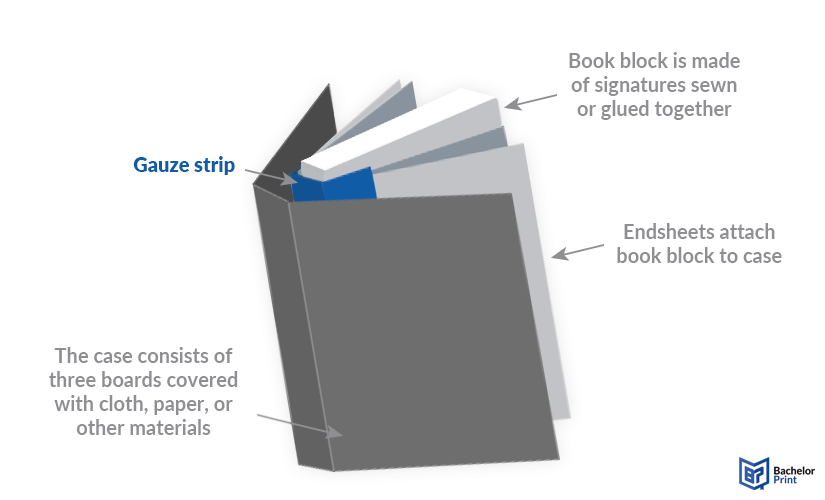

Gauze is a coarse, open-woven fabric to reinforce a book’s spine and to attach the text block securely to the cover. It adds strength at stress points and improves the durability and longevity of the binding.

Definition: Gauze

Gauze in bookbinding is a lightweight, open‐weave fabric used to reinforce and flexibly connect the book spine. Though it shares a name with medical gauze, bookbinding gauze is engineered specifically for durability and archival quality.

Note: Unlike sterile, single‑use medical gauze, bookbinding gauze is acid‑free, reusable in small batches, and designed to bond with adhesives.

Script printing for $0.10

- Script printing in small & large quantities

- Professional script printing for business meetings & seminars

- High-quality script printing for students, faculties & universities

Learn more!

Why use gauze in the spine?

Gauze creates a strong yet flexible hinge, ensuring your book opens smoothly and stands up to frequent use.

Durability & longevity

By bridging the cover, endpapers, and pages, gauze prevents the paper or casing from tearing at the fold.

➜ It helps books resist splitting or cracking even after hundreds of openings.

Flexibility & movement

The open‐weave design bends easily, allowing full opening without resistance.

➜ Yet it still provides enough support to keep the spine square and prevent sagging over time.

Structural reinforcement

Gauze fibers run across the joint between the cover and text block.

➜ This web of threads spreads out the forces exerted when opening, reducing concentrated stress at the hinge.

Uses

Gauze finds its place in both large‑scale print operations and small‑scale craft projects, adapting to the needs of professionals and hobbyists alike.

Types

Choosing the right gauze depends on your project’s needs. Here’s a quick comparison table:

Variants

Features

Weight

30 gsm (lightweight)

Minimal bulk for thin/delicate books

40 gsm (midweight)

Standard balance of support & flexibility

50 gsm+ (heavyweight)

Extra strength for oversized/high use volumes

Adhesive

Pre-gummed (self-adhesive)

Fast application, just moisten & stick

Plain (un-adhesive)

Full control over glue type & coverage

Weave

Plain weave

Smooth, even surface for adhesive

Leno weave

Extra dimensional stability & tear resistance

Specialty options

Acid-free

Prevents paper yellowing

Colored

Blends with cover materials/endpapers

Linen blend

Added tensile strength & subtle texture

Double gauze

Two bonded layers for extra support

Weight variations

Gauze weight is measured in grams per square meter (gsm).

- 30 gsm (lightweight): Perfect for slim notebooks or very delicate pages, like pocket journals.

- 40 gsm (midweight): The workhorse for most hardcovers and trade editions, durable yet slim.

- 50 gsm+ (heavyweight): Ideal for oversized art books or library bindings that see constant handling.

Adhesive

Your choice of gauze adhesive affects workflow and bond strength.

- Pre‑gummed (self‑adhesive): Quick and clean. Just dampen with water and press onto the spine. Great for high‑speed production of catalogs or corporate reports.

- Plain (un‑adhesive): Apply PVA, wheat paste, or specialty glue. Offers flexibility for restoration work or custom projects where precise glue placement matters.

Weave types

The weave pattern you choose affects both how the gauze bonds and how it holds up under stress.

- Plain weave: A simple over‑under pattern providing a smooth surface for even glue application.

- Leno weave: A crossed‑warp fabric structure where adjacent warp threads are twisted around the weft.

Specialty options

Specialty gauzes address long‑term preservation and aesthetic needs.

- Acid‑free: Chemically buffered to neutralize acids, preventing yellowing.

- Colored: Available in neutrals, like gray or beige, to match endpapers or cover cloth.

- Linen blend: Adds linen fibers into the weave for strength and a subtle texture.

- Double gauze: Two bonded layers for greater bulk and tensile strength.

Step-by-step application

Follow these five essential steps to apply gauze cleanly and securely for a professional‑grade spine.

Preparing the text block & covers

- Ensure the pages are square, with trimmed edges and tight signatures.

- Roughen the spine lightly (e.g., with sandpaper) so adhesive grips better.

- Align and clamp the covers to the text block using a book press or weight.

Cut & position the gauze strip

- Measure the spine width plus 5–10 mm on each side for overlap.

- Cut the gauze cleanly with sharp scissors or a rotary cutter.

- Center the gauze over the spine, letting the overlaps rest on the cover boards.

Apply adhesive

- Choose your glue (PVA, wheat paste, other archival adhesives).

- Spread a thin, even coat on the spine and overlap areas using a brush or roller.

- Avoid puddles because too much moisture can warp the spine or bleed through.

Lay in the gauze, press & dry

- Lay in the gauze and smooth out any wrinkles while ensuring full contact.

- Press the fabric into the spine crease with a folding bone or clean roller.

- Keep the book clamped or under weight while the adhesive dries (ca. 1–2 hours).

Trim excess & finish

- Once dry, trim any overhanging gauze flush with the cover edges.

- Sand or burnish the overlaps for a smooth cover transition.

- Check that the hinge opens smoothly and adjust it before covering.

Note: Remember that less is more. Apply only a thin, even coat of glue because too much moisture can warp your spine and extend drying time.

Alternatives & tips

If gauze isn’t on your hand or you need a different approach, consider these handy substitutes and tips:

If you can’t source gauze, reinforced tapes, such as mull strips or H‑band tapes, offer a ready‑to‑use substitute. Woven from paper or cloth, these tapes come in preset widths (often 20 mm–50 mm), so you skip cutting and can apply them by simply brushing on adhesive.

➜ Best for fast commercial runs where consistency matters.

Some fabrics, such as heavy canvas or thick buckram, may seem like sturdy options but can stress your hinge. Under repeated opening and closing, they resist bending and can crack the joint.

➜ To test, fold a sample strip around a dowel; if it springs back without creasing, it’s likely flexible enough.

For ultra-thin volumes, use acid‑free tissue or Japanese mulberry (kozo) paper. These papers readily absorb PVA or wheat paste, forming a bonded layer that holds signatures together.

➜ For water resistance, try glassine; for sheen and extra strength, silk‑reinforced paper.

Hardcover with individual embossing

- Price calculator & 3D live preview

- Professional binding for thesis, dissertation, or books

- Print on demand with fast delivery right to your doorstep

Learn more!

Care & storage

Proper environmental conditions keep gauze and your books in top shape over time.

Pest prevention

- Maintain a clean environment and vacuum surrounding areas, and avoid food or plants near your collections.

Stable temperature

- Maintain storage at 16–22 °C (60–72 °F) to complement humidity control and prevent thermal stress.

Buffering materials

- Include acid‑free interleaving sheets or buffered boards to neutralize any off‑gassing from inks or adhesives.

Breathable packaging

- Store in acid‑free paper boxes or tissue and avoid airtight plastic sleeves that trap moisture.

Note: It’s advisable to inspect your bound volumes every 6 to 12 months for any signs of mold, pests, or adhesive breakdown.

FAQs

Gauze is an open‑weave fabric strip used to reinforce the spine of a book, providing strength and flexibility between the cover boards and text block.

After roughening and clamping the spine, you cut a gauze strip to size, brush on adhesive (PVA or paste), lay the gauze over the spine, smooth it flat, then trim and finish once dry.

For a 100‑page book (≈10 mm spine) about 240 mm tall, allow 5–10 mm overlap each side, so roughly 250–260 mm of gauze per meter‑long roll.

Common substitutes include:

- H‑band tapes

- Reinforced mull

- For very thin volumes: acid‑free tissue or silk paper

Double gauze consists of two superposed layers of thin gauze bonded together, giving extra bulk and tensile strength compared to a single‑layer gauze.