Sticker printing has become increasingly popular for both personal crafts and professional packaging. Whether you’re creating custom decals, product branding, or fun designs, choosing the right type of printer can make a huge difference. There are several printers suited for sticker printing, each with its own pros and cons. In this article, we’ll dive into the types of sticker printers, their benefits, and sticker paper options.

Definition: Sticker printer

A sticker printer is a device specifically used to print adhesive-backed designs onto various materials, such as vinyl, paper, or film. These printers are compatible with specialized sticker rolls or sheets and are commonly used for crafting, branding, labelling, and even photo printing. To cut your sticker designs, a Cricut machine is highly recommended.

Printing services at BachelorPrint

- Individual solutions & personal support

- High print quality & fast production times

- Wide range of print products for every need

Learn more!

Materials

When it comes to sticker printing, there are typically two options: paper-based or vinyl sticker paper.

Sticker paper is a common material for both home and small business sticker printing. It’s made from regular printer paper and works well for indoor use. One big benefit here isn’t just its price, but the amount of print finishes it comes with, e.g., matte, glossy, holographic, and metallic, for a cheap price.

Vinyl sticker paper (or printable vinyl) is a durable, waterproof, and weather-resistant material, which is perfect for transportation decals, laptops, or bottles. It’s a plastic-based material designed to be printed on by inkjet or laser printers, but make sure that the packaging says inkjet/laser-compatible. The table below compares simple sticker paper with vinyl sticker paper.

| Feature | Paper sticker paper | Vinyl sticker paper |

|---|---|---|

| Material base | Paper | Plastic |

| Durability | Low (indoor use) | High (outdoor use) |

| Cost | 💲 | 💲💲 |

| Water resistance | Not water-resistant | Typically waterproof |

| Uses | Labels, scrapbooking | Decals, bumper stickers |

| Sticker residue | Often leaves residue | Often no residue |

Types

Sticker printers can come in the form of desktop printers for commercial purposes or portable printers for quick prints. There are several types, which we’ll explore below.

Laser printers use toner cartridges and heat, making the toner sit on top of the paper, which gives your prints a bold, vibrant look. They tend to be faster than inkjets and produce smudge-resistant text. While laser printers are excellent for everyday document printing — especially for affordable black and white copies — they’re not the best choice for sticker printing, which typically requires full-color output.

Inkjet printers are the best printers for stickers as they offer higher print resolution and image quality. They use printing ink, meaning the pigmented ink soaks into the paper, leading to smooth gradients for photos on inkjet paper but muted colors on plain paper. For frequent printing, consider an ink tank printer as you can easily refill ink cartridges, and this printer is cheaper long-term.

Thermal printers use heat to print without using ink. They’re popular when label printing, as many of them are portable printers that — unlike inkjet and laser printers — can print one durable label at a time. A direct thermal printer label lasts six months or less, while a thermal transfer printer label can typically last up to two years. In a future article, we’ll get more in-depth when it comes to thermal printers, so for now, take a look at our thermal label printer section.

Sticker printer vs. label printer

While both sticker printers and label printers print designs onto adhesive materials, the key difference lies in their primary use and print quality.

Sticker printers are designed to print vibrant designs that are suitable not just for personal or decorative use but also for marketing purposes.

Label printers are typically geared toward business applications like barcodes, shipping labels, or product information, meaning they’re typically text-focused.

Sticker restoration

As most of us know, stickers have a temporary lifespan due to sunlight, moisture, or frequent handling. Premium vinyl stickers generally last 1-5 years, while inexpensive ones might begin to fade or lose adhesion within 1-3 months. Over time, stickers can:

- Delaminate

- Lose stickiness

- Curl at the edges

- Fade from UV exposure

While not all stickers are salvageable, you can try the following tricks to make them re-stick:

- Lamination: If the top layer is peeling away, consider adding a clear laminate sheet or transparent adhesive film to seal and protect the design, thereby preventing further damage.

- Digital rescue: If your sticker fades and you created or downloaded the sticker digitally, reprint it on new sticker paper or vinyl. Going forward, protect new stickers with UV-resistant laminate.

- Add fresh adhesive: For stickers that have lost their stickiness, apply a glue stick, spray adhesive, or double-sided tape to the back. Make sure to clean the surface before applying your sticker.

- Apply gentle heat: If you’re dealing with curling edges, use a hairdryer on low heat to soften the adhesive. Then press the sticker firmly onto the surface using a credit card or roller to flatten it.

Sticker removal

Removing stickers from various surfaces can be quite a sticky situation. However, with these helpful tips, this mess can be easily prevented. To remove stickers, you can use:

- Hot water

- Hair dryer

- Isopropyl alcohol

- Mineral or vegetable oil

- Adhesive remover spray

Waterproofing stickers

If you opted for the cheaper alternative of purchasing paper-based stickers, then don’t worry, because you can still make your custom stickers waterproof. The most popular method that is great for beginners is using self-adhesive laminating sheets. You can find recommended sticker craft supplies on this list.

So, how does it work?

- Print your sticker on regular or glossy sticker paper.

- Cut it out (by hand or with a machine).

- Apply a laminate sheet over the sticker’s surface.

- Trim again if needed.

For the future, make sure to purchase sublimation sticker paper for your custom stickers and then laminate them for UV protection. This waterproof method requires you to own a sublimation printer with sublimation ink installed.

To cut your stickers, a Cricut machine is recommended and since you can’t directly print on your sublimation sticker paper, you also need sublimation paper to then sublimate it on the sticker paper. You can find a YouTube tutorial for this below.

Printing and laminating at BachelorPrint

- Vivid colors & sharp details on premium materials

- Print & laminate menus, posters, certificates & more

- Durable lamination to protect your documents of any size

Learn more!

Benefits

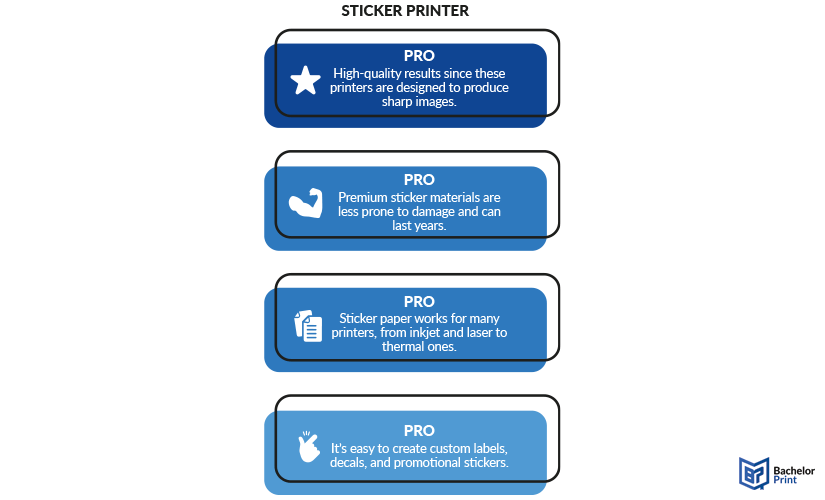

Sticker printers offer numerous advantages, particularly for those looking to create custom stickers at home or for small businesses.

FAQs

- Curling or loose edges? Use light heat and press them flat again.

- Lost stickiness? Apply a glue stick, spray adhesive, or double-sided tape.

- Peeling layers? Cover with clear laminate or tape to hold the surface together.

- Fading or damage? If you have the digital file, reprint the design on fresh sticker paper.

Yes, if you regularly make or sell custom stickers, a dedicated sticker printer can be a smart investment.

The lifespan of a sticker depends on the material, adhesive, and exposure to elements.

- Premium vinyl stickers can last 1-5 years, especially if laminated or used indoors.

- Paper-based stickers may start to fade or peel in 1-6 months, particularly if exposed to moisture or sunlight.

For outdoor use or long-term durability, waterproof vinyl with lamination is your best bet.

For the best results, you’ll want an inkjet printer with good color accuracy and print resolution. However, if you’re printing mostly text-based labels or simple designs, a laser printer can also work, just make sure you’re using laser-compatible sticker paper.