A book press is one of the most essential bookbinding tools, as it plays a key role in ensuring flat and professionally finished books. This tool has been a staple in traditional and modern bindery setups alike. Understanding how it works and why it matters can improve the quality of your bookbinding projects. In this article, we’ll take a closer look at the book press and alternatives.

Inhaltsverzeichnis

Definition: Book press

A book press — also nipping press or screw press — is a bookbinding tool that helps secure glued sections, flatten pages, and align covers with precision by applying even pressure. The plates are made to remain parallel under force to ensure an even press across the entire surface of the book. This pressure helps to flatten pages, set bookbinding glue, and ensure a uniform bond between the book’s components, especially when attaching rigid book boards in hardcover binding. A larger version of a book press is referred to as a standing press, which allows multiple books to be pressed all at once.

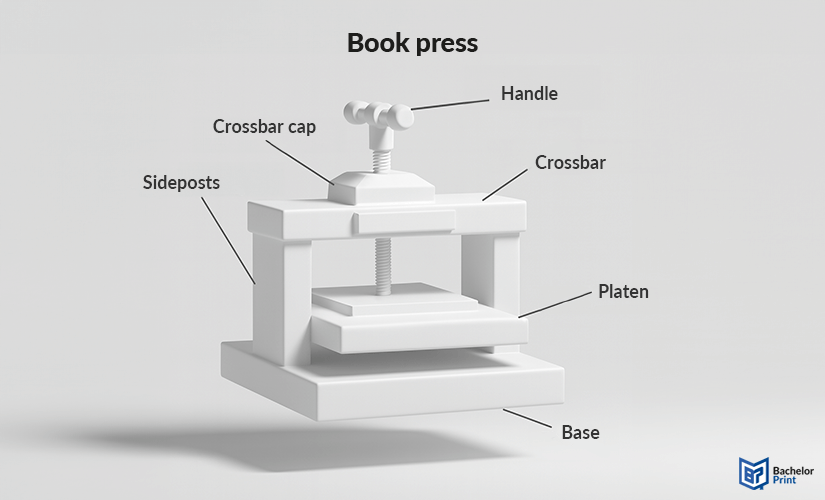

Function of each part

| Part | Function |

|---|---|

| Handle | The handle is used to turn and apply pressure to the platen. Rotating the handle moves the screw mechanism, lowering or raising the platen. |

| The crossbar cap holds the screw mechanism in place and ensures smooth vertical motion of the platen when the handle is turned. | |

| Crossbar | The crossbar provides structural support and stability to the upper part of the press, connecting the two sideposts. |

| Sideposts | Sideposts are vertical supports that connect the base and crossbar, keeping the structure rigid and aligned. |

| Platen | The platen is a flat pressing plate that moves up and down to apply even pressure on the book or paper stack during pressing. |

| Base | The base functions as a bottom platform where the book or material is placed for pressing. It supports the entire structure. |

Hardcover with individual embossing

- Price calculator & 3D live preview

- Professional binding for thesis, dissertation, or books

- Print on demand with fast delivery right to your doorstep

Learn more!

Mechanism

It typically consists of two flat plates — one fixed and one adjustable — that are operated by a screw or hydraulic mechanism to compress the book.

In screw-type presses, turning a large handle tightens the top plate downward; therefore, applying gradual and controlled pressure. These are commonly used in hand bookbinding, especially for pressing signatures after sewing or setting glue. It’s recommended to leave a book in a nipping press overnight or for at least 24 hours.

Hydraulic presses use fluid pressure, either manually pumped or powered by an electric motor, to generate higher and more uniform pressure with less effort. These book presses are ideal for thicker volumes or commercial-scale operations.

Alternatives

Since the book press’s only use is applying consistent pressure, purchasing one may seem like an unnecessary investment to many bookbinders. Below, we have listed some cheaper alternatives to a book press.

- Flower press

- Heavy books or other objects

- DIY book press or flower press

- Wrapping bricks in paper or a plastic bag

- Two cutting boards held together with clamps/screws

Maintenance

Proper care and attention will ensure that a book press remains in excellent working condition for many years. A well-maintained press operates more smoothly, produces better results, and is less likely to require costly repairs. This is why you should:

- Keep pressing surfaces clean and free from glue, dust, or debris.

- For older cast iron models, protect from moisture to avoid corrosion.

- Regularly check and oil screw threads or hydraulic components to prevent rust and sticking.

Printing services at BachelorPrint

- Individual solutions & personal support

- High print quality & fast production times

- Wide range of print products for every need

Learn more!

FAQs

A book press applies even and controlled pressure to books during binding. It flattens pages, sets glue, and aligns covers.

If you don’t have a book press, you can use heavy objects like stacked books, wrapped bricks, or weights to apply constant pressure. You can also use a flower press or clamp your book between two cutting boards.

It’s recommended to keep a book in the press overnight or for at least 24 hours, especially when glue is involved.

Antique book presses were used much like modern ones: to flatten and compress books during binding.