Die cutting is one of the most creative printing terms in modern production. It describes the process of cutting materials, such as paper, cardboard, and plastic, into custom shapes from simple rounded corners to intricate silhouettes. This versatile technique is used in both printing and crafting to give designs a distinctive look and professional finish.

Die-cut explained briefly

Die-cut refers to cutting shapes, windows, or custom outlines in printed materials using a shaped blade (die) to achieve precise, repeatable contours. It’s commonly used for packaging, business cards, labels, and promotional pieces to give them distinctive forms.

Definition: Die-cut

Die cutting is the process of using a custom-shaped metal tool, called a die, to cut materials such as paper, cardboard, fabric, or plastic into precise shapes. Unlike straight cuts or simple trimming, die cutting allows for the creation of unique outlines and intricate designs with perfect consistency across many copies.

The purpose of die cutting is to achieve custom forms and uniform results that cannot be produced with standard cutting tools or scissors. This makes it an essential technique for printing, packaging, stationery, and crafting, where precision and creativity go hand in hand.

Typical applications include:

- Labels and stickers shaped around logos or artworks

- Packaging with cut-out windows or distinctive edges

- Brochures or a folder with decorative shapes and tabs

- Stationery such as invitations, greeting and business cards

Etymology

It’s called “die-cut” because the process uses a die.

- The “die”: Central part of the process, comparable to a cookie cutter

- The “cut”: Die is used to cut or shear the material into a specific shape

- The “die-cut”: The finished piece, shaped by the die, is known as the die-cut

In short, the term “die-cut” directly combines the tool (die) and the action (cut), describing both how and with what the shape is produced.

What is it used for?

Die cutting is used across many creative and industrial fields to produce precise, consistent, and eye-catching designs. It allows materials to be shaped in ways that standard cutting methods can’t achieve.

Die cutting enables unique visual effects in brochures, business cards, and product packaging. Rounded corners, window cut-outs, or decorative silhouettes add a distinctive touch and help designs stand out.

In the world of stationery and hobbies, die cutting is used to add decorative elements to wedding invitations, greeting cards, or scrapbooks, bringing dimension and texture to creative projects.

Because each cut is identical, die cutting is ideal for mass production of labels, stickers, and packaging components. This ensures consistency and precision in every piece.

Beyond paper, die-cutting is also applied in industrial manufacturing to create components such as gaskets, seals, and other industrial parts from materials like foam, felt, rubber, or plastic.

How does die-cutting work?

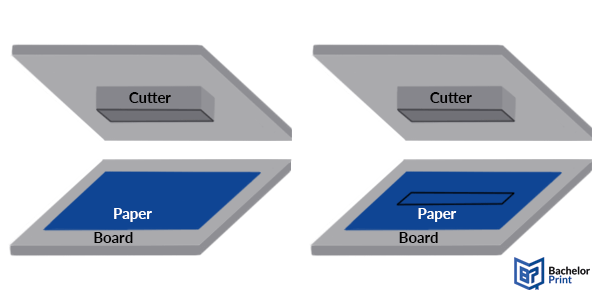

Although die cutting is a precise and technical process, the basic principle is simple: a shaped metal die cuts through a material using pressure.

Step-by-step

Here’s how the process typically works, step by step:

Design the shape

The process begins with a digital design created using a vector file or CAD template. This ensures that every curve, corner, and measurement is defined precisely before production starts. The designer determines where the cuts, folds, or perforations will appear so the final piece aligns perfectly with the printed artwork.

Create the die

Once the design is finalized, a custom-shaped metal blade or steel rule is bent and mounted into a wooden or metal base to form the die. This physical tool acts like a cookie cutter, reproducing the same outline each time it presses into the material. The accuracy of this step determines the overall quality of the final shape.

Prepare the machine

Before cutting begins, the material is positioned or fed into the die cutting press. Depending on the machine type, this setup can be done manually for smaller runs or automatically in industrial systems. Proper alignment at this stage is crucial to ensure that the die lines up correctly with any printed artwork or pre-scored areas.

Apply pressure

The die cutting press then applies uniform pressure, forcing the sharp edges of the die through the material. This can be achieved through hydraulic, mechanical, or rotary motion, depending on the equipment. The combination of precision and controlled force ensures that the cuts are clean and true to the original design.

Remove waste

After cutting, any excess material or leftover edges are stripped away, leaving behind the finished shape. This step reveals the final die-cut piece, which is now ready for further finishing processes, such as embossing, foil stamping, or lamination. This result is a perfectly formed product that matches the intended design down to the smallest detail.

Cutting mechanism

Die cutting works by combining pressure and precision. The sharp metal edges of the die push into the surface of the material until it separates cleanly along the intended shape. The same principle is also used in texture, separation lines, or folding guides rather than full cuts.

This controlled use of force allows die cutting to deliver exact, repeatable shapes across large production runs, making it one of the most reliable processes in modern print finishing.

Printing and laminating at BachelorPrint

- Vivid colors & sharp details on premium materials

- Print & laminate menus, posters, certificates & more

- Durable lamination to protect your documents of any size

Learn more!

Types of machines

There are several types of die cutting machines, each suited to different production needs, materials, and levels of precision.

Manual machines

Manual die cutters are hand-operated devices that use pressure from rollers or cranks to push the material through a metal die. Common in crafts and small creative projects.

Ideal for whom?

Hobbyists, small studios, and designers creating limited or decorative pieces.

✅ Pro: Affordable, easy to use, and requires no electricity.

❌ Con: Limited cutting size and precision; unsuitable for large runs.

Digital machines

Digital die cutters work without a physical die. They use a computer-controlled blade or laser to cut directly from a digital file, following exact vector outlines.

Ideal for whom?

Designers, print shops, and businesses producing prototypes or small custom batches.

✅ Pro: No setup or tooling cost; perfect for short runs and intricate designs.

❌ Con: Slower than rotary systems for high-volume production; limited for thick materials.

Rotary die cutting

These machines use a cylindrical die that rotates continuously while the material feeds through. They provide high-speed, consistent cutting, ideal for mass production.

Ideal for whom?

Industrial printers and packaging manufacturers handling large production runs.

✅ Pro: Extremely efficient and reliable for continuous cutting.

❌ Con: High setup cost and less flexibility for frequent design changes.

Semi-rotary die cutting

Semi-rotary systems combine the speed of rotary cutting with the flexibility of adjustable feeding. The material moves back and forth beneath a single rotating die, enabling efficient custom cuts.

Ideal for whom?

Label producers and converters needing frequent design changes with fast turnaround.

✅ Pro: Flexible and efficient; reduces downtime between jobs.

❌ Con: Slightly slower than full rotary; limited for very thick materials.

Flatbed die cutting

Flatbed cutters use a flat press to apply pressure vertically onto the material. The die cuts down from above, allowing for precise cuts on thick or rigid materials.

Ideal for whom?

Printers and manufacturers producing packaging, displays, or detailed prototypes.

✅ Pro: High precision, excellent for complex or thick materials.

❌ Con: Slower and more expensive setup than rotary systems.

Benefits

Die cutting offers a wide range of advantages for both creative and commercial printing projects, which is why it’s one of the most popular finishing techniques in modern print production:

✅ Works with many materials

✅ Increases brand recognition

✅ Adds texture and tactical value

✅ Enables unique, custom shapes

✅ Delivers precision and consistency

Cost factors & challenges

While die cutting delivers high-quality, creative results, it can also be one of the more costly finishing techniques in printing. The total cost depends largely on the complexity of the design, the materials used, and the precision required.

Why is die-cutting expensive?

- Complex shapes or fine details

- Manual adjustments and waste removal

- Custom die creation (setup time and materials)

What are typical die-cut issues?

Even with high-quality equipment, certain problems can occur during the process:

❌ Paper tearing on thin stocks

❌ Dull blades causing rough edges

❌ Misaligned cuts due to poor registration

❌ Pressure inconsistencies on thick materials

Note: Use sharp dies, consistent pressure, and registration marks to prevent quality issues.

Modern alternatives

Although traditional die-cutting remains a staple in print finishing, modern technologies have introduced faster, more flexible, and often more cost-effective alternatives. These methods eliminate the need for physical dies, making them ideal for short runs and complex designs.

Laser cutting uses a focused laser beam to precisely cut or engrave materials. It’s ideal for short runs, prototypes, or intricate shapes, as there are no tooling costs or setup delays.

- Works with paper, acrylic, wood, and plastics

- Produces clean, sealed edges and detailed cuts

- Commonly used in packaging design and custom stationery

Digital cutting plotters rely on a computer-controlled blade to follow a digital design. This method is flexible and fast, perfect for personalized designs and small-batch production.

- No need for a physical die

- Ideal for on-demand printing and variable data projects

- Often used for labels, stickers, and promotional materials

CNC (Computer Numerical Control) systems are primarily used in industrial manufacturing. They can cut, engrave, or mill thicker or rigid materials like foam, wood, or metal with extreme precision.

- Suitable for high-end packaging, signage, or prototype creation

- Offers exceptional accuracy and repeatability

Comparison

Here is a comparison of every modern method with traditional die cutting.

Method

Strength

Use

Traditional

Efficient for mass production

Packaging, stationery

Laser

Very precise, no tooling

Short runs, detailed designs

Digital

Fast setup, flexible

Stickers, labels

CNC

Handles thick materials

Industrial prototypes

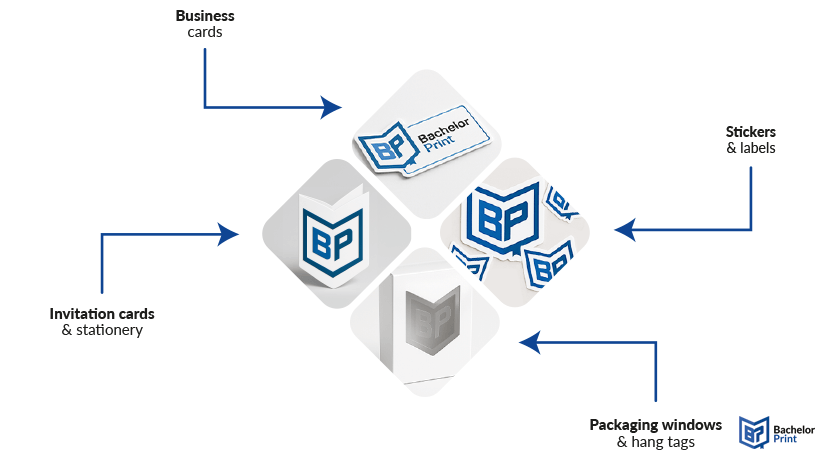

Examples

These examples show how different materials and shapes can transform ordinary products into eye-catching, professional pieces:

Business cards

Rounded corners, cut-out logos, or layered shapes make business cards feel more distinctive and memorable, enhancing their impact.

Stickers & labels

Custom-shaped stickers or labels cut precisely around the artwork help products stand out on shelves and add a professional finish to packaging.

Invitation cards & stationery

Wedding invitations, greeting cards, and event stationery often use decorative die-cut edges or window details for an elegant, handcrafted look.

Packaging windows & hang tags

Die-cut windows reveal the product inside a box, while uniquely shaped hang tags enhance brand identity and design appeal.

Easy A6 printing at BachelorPrint

- Vivid colors & precise details on high-quality materials

- Print A6 invitations & cards in premium quality from CAN$0.13

- Perfect for personal messages, events & professional mailings

Learn more!

FAQs

Die cutting is the process of using a custom-shaped metal tool, called a die, to cut materials like paper, cardboard, or plastic into precise shapes.

A Cricut is a type of electronic die cutting machine that uses a computer-controlled blade to cut shapes directly from digital designs. While die cutting is the general term for this process, Cricut refers to a specific brand of smart cutting machines popular for crafting and small creative projects.

Die cutting can be expensive for short runs because each design needs a custom die. Complex shapes may require manual setup, and thin materials can tear if the pressure is too high.

In die cutting, the blade cuts completely through the material. Kiss cutting only cuts through the top layer, leaving the backing intact.

Die cutting uses a metal die and physical pressure to create shapes, while laser cutting uses a focused laser beam.